Solutions

Our Facilities

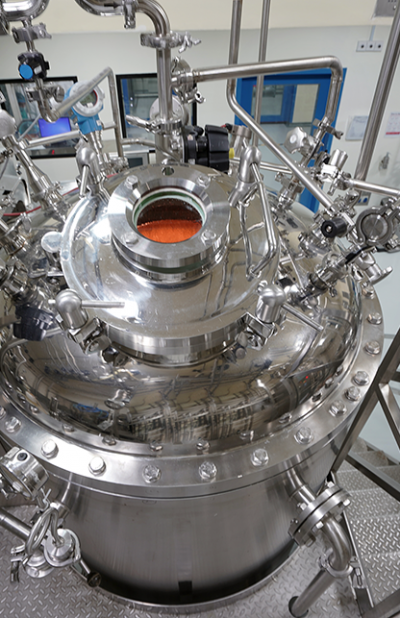

Final Vaccine Formulation

There are three fully automated production lines, each line has a sterile room for the final vaccine formulation, including mixing antigens with the appropriate immunity adjuvant and excipients under sterile air and positive pressure to avoid environmental contamination. These lines consist of:

Freeze dried live vaccines

- Technique used to produce live viral vaccines for poultry and livestock.

- The vaccine is mixed with stabilizers and dried in special machines for lyophilization.

- The vaccine can be administered through drinking water or injection.

Inactivated vaccines

Production under high positive pressure using HEPA filtered sterile air to avoid environmental impacts in the efficacy of the final vaccine.

Diluents for vaccines

A sterile diluent is used to dissolve the final vaccine to ensure the highest rate of efficacy.

Each production line is equipped with international technologies at the forefront of the industry. The lines have high production capacities with production speeds reaching up to 10,000 vials per hour. Thus, Klybeck Life Sciences can cater to the needs of both the local and international markets.